Introduction

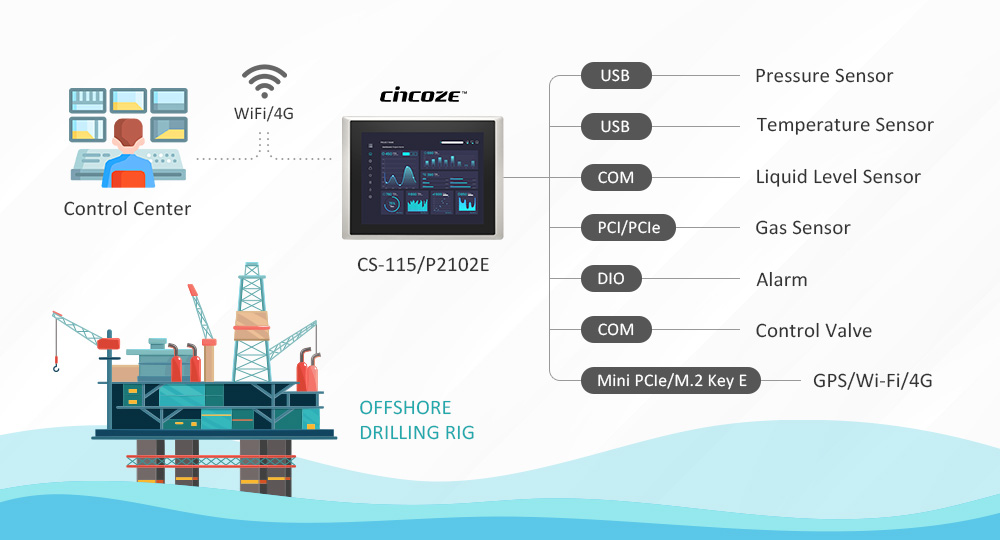

According to statistics from the globally recognized data platform Statista by 2027, the number of cruise users is expected to reach 32.53 million. Given the critical role of cruise ships in passenger transportation, onboard systems, such as engine monitoring, power management, and safety systems, are essential for closely overseeing their operation.

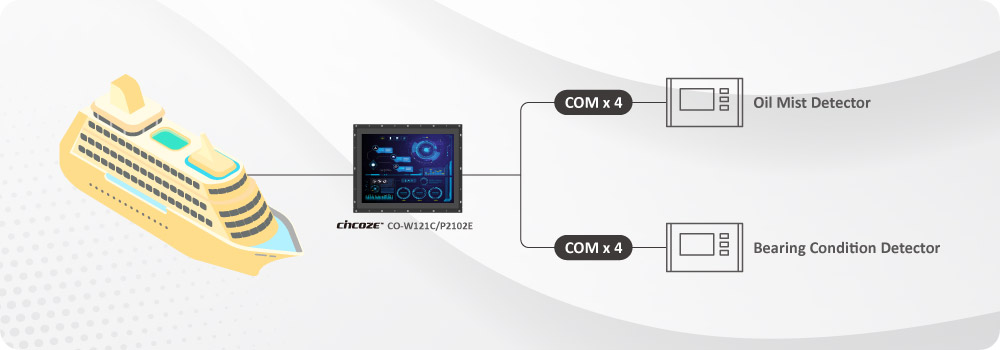

Cincoze’s customer, a renowned Central European systems integrator selected Cincoze’s open frame panel PC (CO-W121C/P2102E) to monitor cruise ship engines. This panel PC connects multiple sensors, collecting data for analysis and enabling preventive maintenance, thereby avoiding engine overheating, shutdowns, or component damage due to bearing wear or excessive oil mist. The Cincoze CO-W121C/P2102E helps improve cruise ship engine safety and minimizes engine maintenance costs.

Customer Requirements

Open Frame Design

The customer requires a high performance industrial panel PC to serve as the core of cruise ship engine monitoring. This panel PC receives real-time data from sensors, visualizes it, and enables operators to immediately understand the engine’s status for adjustments and predictive maintenance. The customers also wanted the industrial panel PC to align with the other equipment in the control room, so they needed an open frame industrial panel PC.

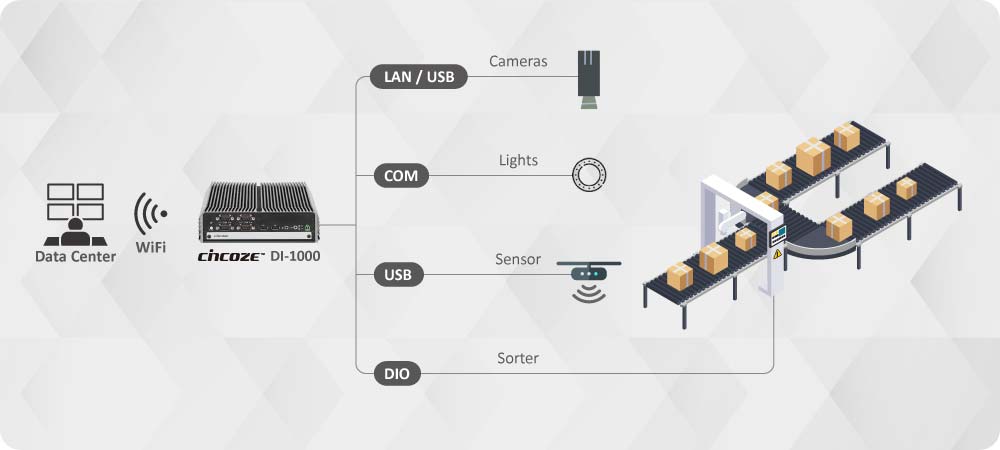

At Least Six COM Ports

As cruise ship engine oil mist and bearing monitoring rely on data captured by sensors, a computer that supports at least 6 COM ports is required to connect to multiple sensors for real-time data acquisition.

Withstand the Harsh Maritime Environment

Cruise ships potentially experience significant temperature and humidity variations, requiring the computer to endure harsh weather conditions, impacts from waves, ship vibrations, and electromagnetic interference. A rugged and highly reliable industrial panel PC is needed to prevent monitoring interruptions and difficult maintenance situations at sea due to malfunctions.

Why Cincoze?

Cincoze Open Frame Panel PC

The Cincoze open frame panel PCs (CO-100/P series) offer a choice among Intel® Core™ U, Pentium®, or Atom® processors to meet diverse computer performance needs. Beyond providing high-performance data processing and graphics capabilities, their easy installation is a significant highlight. The exclusive adjustable mounting bracket (Patent No.: D224544, D224545, I802427) features thickness adjustment settings and two locking methods (panel or boss type), enhancing convenience for integration into ship control cabinets.

Cincoze open frame panel PCs (CO-100/P series) offer a wide range of options, with sizes from 19” to 21”, 5:4 and 16:9 display ratios, and multi-point capacitive touch.

Flexible Expansion

The monitoring system for mist and bearing in cruise ship engines relies on multiple sensors to capture data. The CO-W121C/P2102E is equipped with 4 built-in COM ports, and with Cincoze’s unique MEC module, it can expand up to 8 COM ports, effectively fulfilling the requirements. Additionally, two Mini-PCIe slots and one PCI/PCIe x4 slot cater to the needs of data acquisition cards or I/O expansion.

Easy to Maintain and Upgrade

Cruise ships may face challenges in equipment upgrades or maintenance. With Cincoze’s CDS patented technology (Patent No. M482908), the CO-W121C/P2102E makes replacing screens, upgrading systems, or troubleshooting easy. Only a single component needs to be quickly replaced to get the machine online and reduce downtime.

Rugged and Reliable

The CO-W121C/P2102E has industrial-grade protections, such as a fanless design, wide operating temperature (0°C to 60°C), wide voltage (9 to 48 VDC), and an IP65 waterproof and dustproof front panel. These features make it suitable for long-term operation in the harsh maritime environment.